Measuring Your Success With Torque Indicators

By: Nick Gill

Working in the field operations department at Danbro Distributors, my primary duties include setting up new contractors to become installers. This requires equipment and training necessary to embark on their new venture of installing helical piles. I also help existing contractors keep up to speed with new drive heads, torque indicators, and mounting brackets to keep their equipment functioning at peak performance.

We work with a large network of equipment manufacturers to meet customers’ needs and requirements for projects large and small. In this blog, I am going to talk about the most important factor in the equipment portion of the helical pile business – torque indicators.

The torque indicator measures the torque applied to the pile as it is screwed into the ground. For those new to helical piles, torque directly correlates to the load that the pile can hold. Without measuring torque, you do not know what capacity the pile can hold. There are several different types of torque indicators: Shear Pin indicators, pressure gauges, strain gauges, and digital pressure torque indicators. Below is a summary of these products and what Danbro recommends from our combined 75 years of experience in this industry.

Shear Pin Indicators

The history of torque indicators starts with Shear Pin indicators and hydraulic pressure gauges. A shear pin indicator takes anywhere from 1 to 20 shear pins. Each shear pin is rated to break at 500-foot-pounds of torque, so if you needed to install a helical pile to 4,000-foot-pounds of torque, you would load the shear pin indicator with 8 pins.

This system is very user-friendly to operate and straightforward for anyone on a pile crew to use.

With this system, however, broken shear pins can get lodged in the torque indicator and it can take time to remove them before installing the next pile. Some downtime is encountered while stopping to reload the shear pin indicator. There is also additional length in your tool string, so it is not ideal for low headroom situations.

Dial Pressure Gauges

Hydraulic pressure gauges are dial pressure gauges that get plumbed into the lines or somewhere on the machine and the hydraulic pressures applied to the drive head have a very rough correlation to the load on the pile.

This system has no additional length in the tool string, which is a major help in low headroom situations.

With this system, however, there is no accurate calibration without setting benchmarks on the gauges. A benchmark test with your gauge proceeds as follows: Install a helical pile with a shear pin indicator or strain gauge and get your required installation torque. If, for example, your required installation torque is 5,000-foot-pounds, when you achieve the required torque, at that point you would reference your gauges. Now reference the pressure or PSI (pounds per square inch) on your gauge. If the gauge records 2,000 PSI, then you know that 2,000 PSI equals 5,000 foot pounds of torque. From this point, you can remove the strain gauge or shear pin indicator and install the helical piles to 2,000 pounds per square inch, confident that you are achieving the necessary torque.

Some contractors get their gauges calibrated from outside calibration services; this is okay, provided they have the necessary paperwork and documentation from their service. However, since hydraulic oil runs thick in cold weather and thin in warm weather, your readings can vary.

Danbro offers accurate, calibrated, and easy-to-use torque indicators for your helical pile installation needs. We carry strain gauges as well as digital reading torque indicators. Below.is a summary of the pros and cons of various torque gauges

Strain Gauges

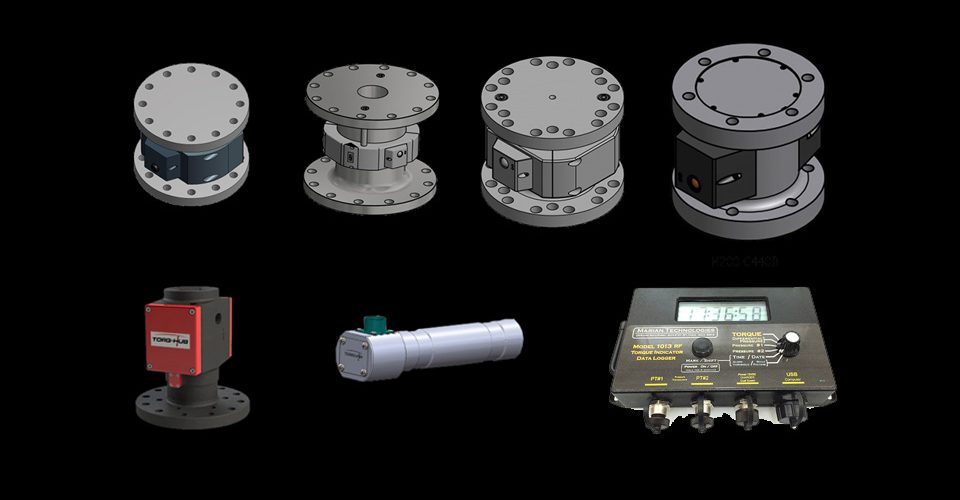

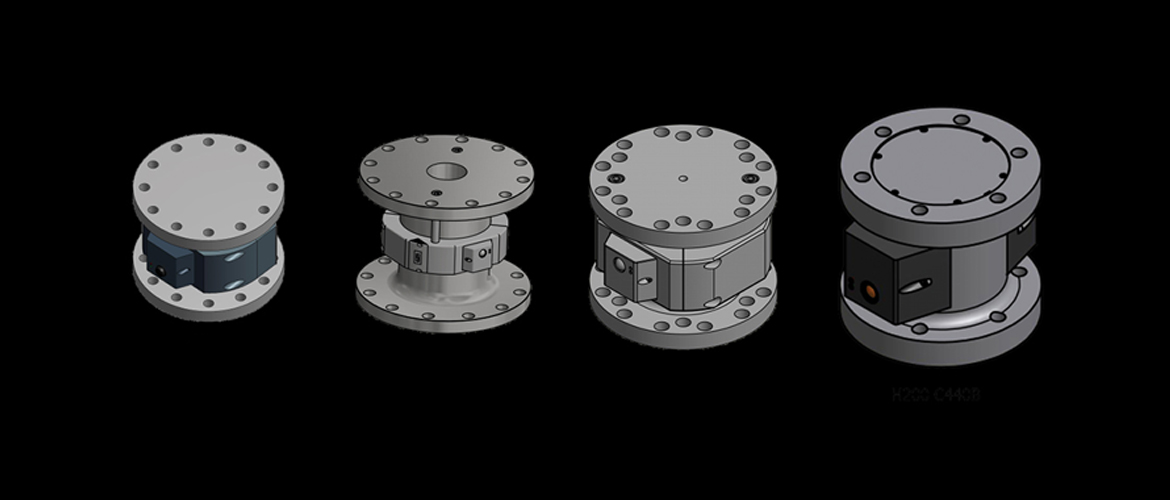

We work with two manufacturers that manufacture strain gauges for helical pile installation. Concept Torque Solutions from Alberta Canada manufactures the Torq Hub and Torq Pin; Pro Dig from Kansas manufactures the Intelli Tork. They each make strain gauges that are highly accurate for helical pile installation measurement.

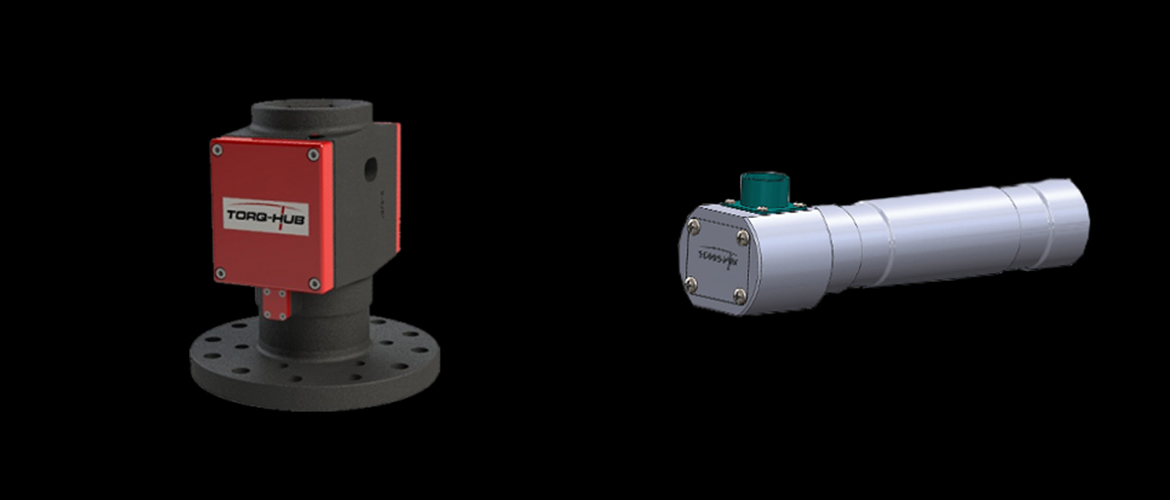

Torq Hub

Calibrated up to 20,000-foot-pounds of torque, the Torq Hub is a strain gauge that has a casted hub at the top, connecting either a 2”, 2.5”, or 3” hex on a drive head. The bottom of the Torq Hub has both a 6-bolt and a12-bolt flange for your tooling. It comes with a display screen that mounts in the cab and plugs into a cigarette lighter outlet in the cab of your machine. Utilizing its own internal WiFi, the Torq Hub displays the installation torque from the pile.

A very accurate torque monitoring device, the Torq Hub will plot your torque per pile for submittals or you can set a target torque which will set an alarm once that torque is reached.

Because the hub is cast to a certain hex size, if you get one with a 2.5-inch hex, you cannot put it on your 2” hex or 3” hex drive, unless you use a hex adapter. If necessary, we can provide an adaptor for you.

In some job-specific situations, the wireless reading can lose connection. For example, if you are installing piles in a trench box or installing tiebacks, and your drive string is on the other side of the sheeting or the bank where you’re working, the wireless connection may be lost.

Of course, if your machine does not have a cigarette lighter outlet, you will need to get creative with how to power the display screen.

Torq Pin

The Torq Pin is designed and works in a similar fashion, except it goes in the bail ears of your drive head. This is also a very accurate way to measure torque on piles.

This system does not add length to your drive string and is ideal for low headroom situations. Additionally, the same pin will fit on multiple sized drive heads depending on the size of the bail ears; they are typically built for 45-millimeter pin holes on the bail ears of drive heads.

In this system, the pin will only work with certain manufacturers’ drive head bail ears; therefore, if you own multiple brands, it may not fit on all of them.

Intelli Tork

The Intelli Tork is a strain gauge that has a bolt circle on the top and bottom of it; any size tool, Kelly bar, or hub adapter can bolt onto it. With the appropriate app, this gauge’s data can be viewed by many WiFi smart devices, such as your iPhone.

In addition to highly accurate torque readings, this torque indicator can not only log the torque data, but also provides other data such as the angle of the pile, revolutions-per-second, and the depth. This device also has a torque alarm.

Digital Torque Indicator

We work with Marian Technologies which manufactures PT Tracker, a digital pressure torque indicator. Plumbed up similar to pressure gauges mentioned earlier in this article, this torque indicator is far more accurate than conventional pressure gauges. This torque indicator converts the scale factor from the drive head and displays real-time torque.

The scale factor is the drive head manufacturer-recommended number for foot-pound of torque to the PSI it takes to create that foot-pound of torque. For example, if it takes 3.5 pounds per square inch to create one foot-pound of torque for a specific drive head, the 3.5 is entered into the PT Tracker’s software program; it reads the PSI and displays the torque based on that scale factor, so when 3,000 pounds per square inch is applied to the drive head, the PT tracker will read 10,500.

This is far more accurate because it is monitors the pressure being applied to the drive head and is calculated using the rating of the drive head, not the pressure from the machine.

This system adds no length to your drive string since it is plumbed into the hoses. It comes calibrated from the manufacturer and is accepted for installation use nationwide compared to the original style of using conventional dial pressure gauges. This device logs your torque; it can plot this data on a graph for review at the end of a job. This unit can also give you pressure readings as well. Contractors use the torque setting for helical pile installation and, at the flip of a switch, they are reading pressures to monitor STELCOR drilled-in displacement micropiles.

This system requires set up on a computer program. The scale factor is a specific number for each and every drive head; therefore, if you have a 12K drive head that is set up for the PT tracker, you will have to change the scale factor on the computer program before you use the PT tracker on another drive. This method is very accurate; however, we have seen 1 to 5 percent difference between this and a strain gauge.

All of the above systems work very well. I have set all of these systems up and used all of them on jobs up and down the east coast, ranging from small residential additions to use on the runway at Ronald Reagan International Airport.

Based on your equipment or the nature of the work that you do, you may be better served by one product or another. We will ask the right questions and recommend a torque indicator that best fits your needs. Don’t hesitate to reach out to us to find the best unit for your company.