Helical piers and anchors are a great alternative to many other deep foundation products as they mitigate or eliminate many site issues including vibration, spoils, access, and mobilization.

However, like all piling systems, they have design limitations that can limit or constrain their use. Helicals are slender, segmented piles, ideal for getting into tight spaces with limited overhead, but if there is not enough shear strength in the soil, they are susceptible to lateral or buckling.

They are made of steel, so corrosion is also a consideration. A geotechnical investigation can quickly determine if lateral, buckling, or corrosion are at issue and what corrective measures need to be taken.

Our mantra at Danbro is: “When in doubt, grout!” Encasing a helical pile in grout not only deals with any design limitations, but the grout column increases the section modulus and provides increased capacity through friction.

How To Encase A Helical Pile In Grout

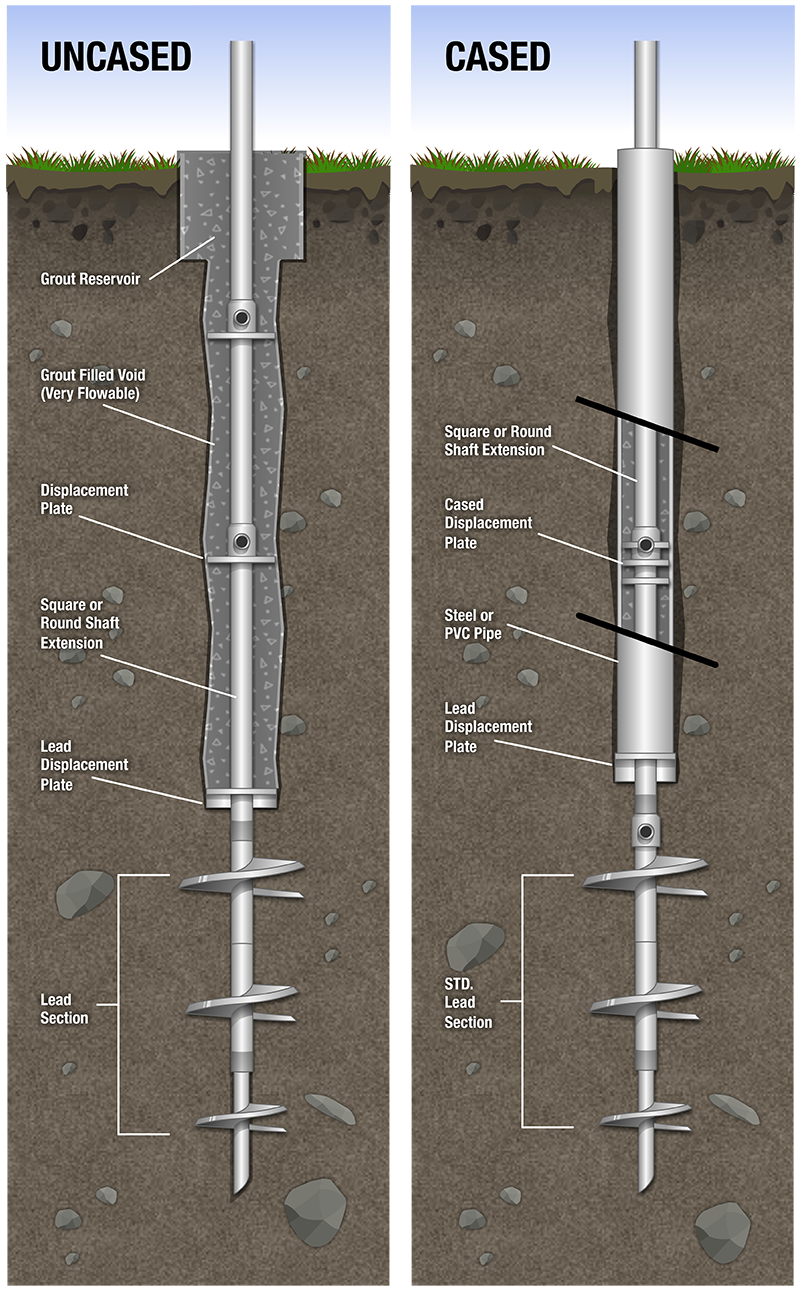

- A traditional helical lead section with either a square or round shaft is advanced into the soil.

- A circular displacement plate is slipped on the shaft as a helical extension is bolted to the lead section.

- The displacement plates attached to the helical extension spin through the soil, pushing away and compacting the soil around the shaft. This creates a cylindrical void around the shaft which is filled by the gravity flow of grout from the reservoir at the surface.

- Uncased piles are filled immediately as the pile is installed; the cased version can be filled immediately or after the pile is terminated.

The grouted helical micropile has all the advantages of a traditional helical pile, plus:

- The grout column, either cased or uncased, is pulled down around the length of the extensions.

- It protects steel, eliminates corrosion, and stiffens the pile.

- It increases the capacity from friction on the grout column.

- It eliminates design limitations.

- Grouted Helicals can be extended above grade.

Whether you need helical piles or grouted helical micropiles, cased or uncased, Danbro has a deep foundation pile which can achieve the load, is gentle to the environment, and eliminates or mitigates site concerns.

We also provide engineering, training, and site-specific support to straighten out the learning curve. That’s what makes the Danbro Difference.

Case Studies

Click here to see examples of grouted helical pile jobs in the Case Studies section of our website.